Silo scraper systems

Silo scraper systems

GSI offers commercial solutions for unloading silos from 24″ (7.31 m) to 120″ (36.57 m) in diameter. Unloading auger 8″ (203.2mm), 254mm) or 12″ (304.8mm) tube diameter. If you are transporting a large amount of grain, you may need a commercial type unloading platform, even if you have a small silo. the system is more robust.

Motor bases

Industrial grade scraper motor mounts are made from steel plates 3/16 in. (4.76 mm) thick. All bearings are insulated, self-aligning, lubricated and housed in a cast block housing.

Sliding doors

All covers work with a gear cover control mechanism.

With a simple spindle change operation, either the center cover or the intermediate cover can be opened and closed.

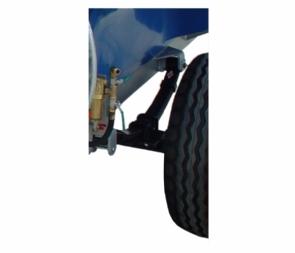

Carriers

For large silos 48 ft (14.63 m) and larger, bottom scraper holders are available. The carrier wheels move along the floor of the silo, helping to support the auger and its protection. If your hopper is 90 feet (27.43 m) or longer, the conveyor is in two parts.

Hoppers

Durable commercial bunker unloading platforms covers can be used for a ventilation system, a ducted ventilation system, or a ventilation system buried in concrete, the base of which is completely covered with perforated sheet. The lids are made from 1/4″ (6.35 mm) thick steel and can be opened and closed with little effort thanks to durable bearings.

Engine heads

Horizontal power heads are available in 6″ (152.4mm), 8″ (203.2mm), 10″ (254mm) and 12″ (304.8mm). Depending on the machine, they can be single or double direct belt driven. Commercial types can be with 2, 3 or 4 belts or oil bath gear system. Silos with a 25° slope are used in silos with a maximum diameter of 75 feet (22.86 m). 6″ (152.4 mm) (horizontal) to 6″ (152.4 mm) (tilted), 6″ (152.4 mm) to 8″ (203.2 mm), 8″ ( 203.2mm) to 8″ (203.2mm), 8″ They come in sizes (203.2mm) to 10″ (254mm) or 10″ (254mm) to 12″ (304.8mm) ).

If you need maximum performance with a smooth grain flow, we recommend using a horizontal auger platform with a higher angle of inclination and a smaller diameter. The 5′ (1.52m) length provides approximately 2″ (0.61m) additional dump height. All slopes are equipped with 2 or 3 straps and include an adjustable support post. The optional caster kit can also be used to carry the support stand.

In silos 36 ft (10.97 m) or smaller in diameter, the standard 14 ft 6 in (4.42 m) vertical type auger can be easily unloaded directly onto a truck, trailer or mill. These power units are located both vertically and horizontally under the silo. Auger drive requires a single motor system. The linkage is mounted in an oil-bathed right angle gearbox. It is driven by a power take-off or an electric motor.

The standard vertical type auger manufacturing package includes a 3´ (.92m) length 45° inclined auger tube, base support and silo wall mounting clamps. An optional kit is also available to connect the 8″ (203.2mm) vertical type auger to the 6″ (152.4mm) discharge tube. The 16´ 6″ (5.03m) long commercial type double motor vertical type auger can be used in silos with 24´ (7.32m) and 90´ (27.43m) diameters.

Offered in 8″ (203.2mm) and 10″ (254mm) diameters, this system has a dual motor system. A direct-tie-belt motor or a 3:1 oil-bathed reducer system can be used to run the motor of the horizontal section.

As with the standard, the package includes a 3´ (.92m) long 45° discharge inclination tube, base support and silo wall mounting clamps. An optional kit is also available for connection to a 10″ (254mm) vertical type 8″ (203.2mm) discharge tube.

Thanks to the rubber wheel, the auger moves and the bottom scraper touches the bottom of the silo.

The balance of the auger against the grain weight is ensured by the bearings.

Tags: Slio manufacturing, Silo companies, Silo production, Silo systems, Grain silos, Wheat silo, Corn silo, Truck and Truck Unloading Platforms